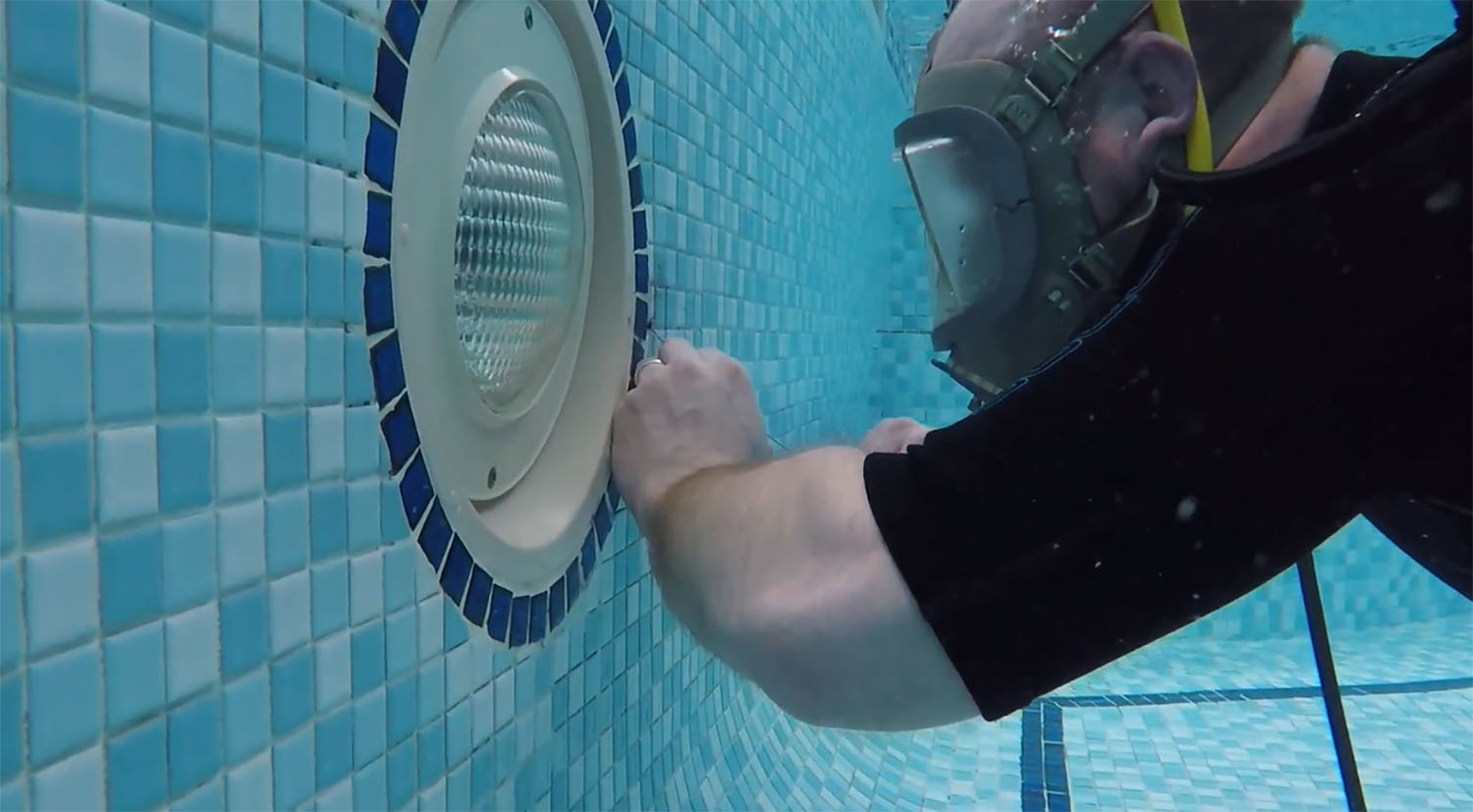

UK Diveworks provide commercial swimming pool services for the installation and replacement of handrails, ladders, striker plates, grilles, tile protection plates, anchor points for lane marker connections, underwater lights, starter blocks and blanking plates.

We use professional and the most up to date equipment for all our projects such as the nemo underwater cordless drill with hammer action capability.

Register for annual checks

call 01202 932933

Handrails for swimming pools are essential safety features that provide support and stability to swimmers entering and exiting the pool. They are typically made from durable materials such as stainless steel or powder-coated aluminum, designed to withstand exposure to water and harsh pool chemicals.

There are several potential issues that can arise with handrails in commercial swimming pools. Some of the common problems include:

Any questions?

call us on 01202 932933

It is essential to prioritize safety and compliance throughout the ladder replacement process. The team at UK Diveworks can provide expert guidance tailored to your situation.

Here are several potential issues that can arise with ladders in commercial swimming pools.

There are several issues that can occur with striker plates in commercial swimming pools. Here are some potential problems:

Potential issues that can arise with grilles in commercial swimming pools include:

Annual Inspection

call us on 01202 932933

Swimming pool tile protection plates are installed to protect the tiles and provide a surface for swimmers to push off from. While they serve a useful purpose, there are a few potential issues that can arise with these plates:

All grilles should be regularly inspected and if any of the above problems should occur UK Diveworks are able to provide expert advice and services.

In commercial swimming pools, anchor points for lane marker connections are typically used to secure and hold the lane lines in place. These anchor points are designed to prevent the lane lines from moving or drifting during swimming activities. The specific design and configuration of anchor points may vary depending on the pool manufacturer and the type of lane line system being used.

To mitigate these potential problems, it is essential to ensure that the anchor points used for lane markers in swimming pools are of high quality, installed correctly, and regularly inspected for any signs of damage or wear.

There are several potential issues that can arise with underwater lights in commercial swimming pools. Here are some common problems:

It is important for commercial pool operators to regularly inspect, maintain, and replace underwater lights as needed to ensure optimal performance, safety, and visual appeal. Additionally, engaging qualified professionals such as UK Diveworks for installation and maintenance can help mitigate many of these potential issues.

Any questions?

call us on 01202 932933

There are several issues that can arise with starter blocks. We have listed a number of problem areas.

it is crucial to engage professionals such as UK Diveworks, experienced in servicing, replacement and maintenance. Regular inspections, adherence to regulations, and prompt repairs or replacements when necessary can help prevent accidents and maintain a safe swimming environment.

Blanking plates are used in commercial swimming pools to cover or block off certain areas, such as drain outlets or inlets, for various reasons. While blanking plates can serve a useful purpose, there are several potential issues that can arise when using them in commercial swimming pools.

To mitigate these potential issues, it is essential to follow proper installation guidelines, use high-quality blanking plates designed for commercial swimming pools, and regularly inspect and maintain the plates to ensure their integrity. It's also important to consult with pool professionals or engineers who specialize in commercial pool maintenance to ensure the appropriate use of blanking plates and adherence to safety standards.